[

Tesla plans to fend off cheaper competitors from China with a $25,000 electrical automotive. However first it should overhaul the 100-year-old manufacturing course of pioneered by Henry Ford.

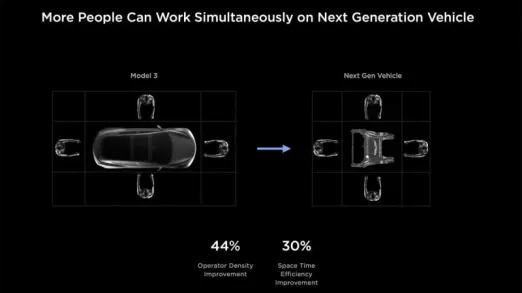

The corporate is transferring towards an “unboxed” strategy, which is extra like constructing Legos than a standard manufacturing line. As a substitute of transferring a big, rectangular automotive alongside a linear conveyor belt, the elements are assembled collectively in devoted areas after which all of the sub-assemblies are put collectively on the finish. Tesla says the change might cut back manufacturing footprint by greater than 40%, permitting the carmaker to construct future vegetation a lot quicker and at a decrease expense.

Tesla says the brand new meeting course of might halve manufacturing prices whether it is profitable. That shall be key to delivering an inexpensive automotive to spice up demand that has slowed just lately and put stress on the electric-car maker's inventory value. Tesla shares have fallen 29% up to now this 12 months, whereas the S&P 500 has gained 10% throughout the identical interval.

“If we're going to scale the way in which we need to, we're going to need to rethink manufacturing,” Lars Moravy, Tesla's vp of car engineering, stated in the course of the firm's March 2023 investor day.

The issue is that buyers haven't heard many particulars about how Tesla has progressed with the thought since then, at the same time as Chinese language automakers have lower prices and Detroit carmakers have Has refocused its efforts on cheaper fashions.

On the corporate's most up-to-date earnings name in January, Chief Government Officer Elon Musk caught to the standard speaking factors, saying solely that Tesla is “far forward” in making an inexpensive automotive, with manufacturing scheduled to start late subsequent 12 months. hopefully. Though he talked about the brand new “revolutionary manufacturing system”, calling it “by a substantial margin, extra superior than any automotive manufacturing system on the planet”, he didn’t elaborate.

Musk is infamous for lacking deadlines, and a few on Wall Avenue doubt Musk can meet his already delayed deadline — he first teased a $25,000 EV means again in 2020 — in need of the financial savings purpose. Little or no. Tesla's technique is unproven, and should have its personal inefficiencies and dangers. A latest evaluation from Bloomberg Intelligence estimated that the brand new modular manufacturing course of would lower prices by 33% – not half.

Tesla didn’t reply to requests for remark.

Within the absence of particulars, some individuals are taking it upon themselves to determine how properly the system would possibly work. Matthew Vachaparampil, CEO of engineering and automotive benchmarking agency Caresoft, stated his firm's engineers spent 200,000 hours making a digital duplicate of Tesla's unboxed platform. He discovered Musk's ambitions to be technically possible, and Vachaparampil stated they might make “large monetary sense” in the event that they have been achieved.

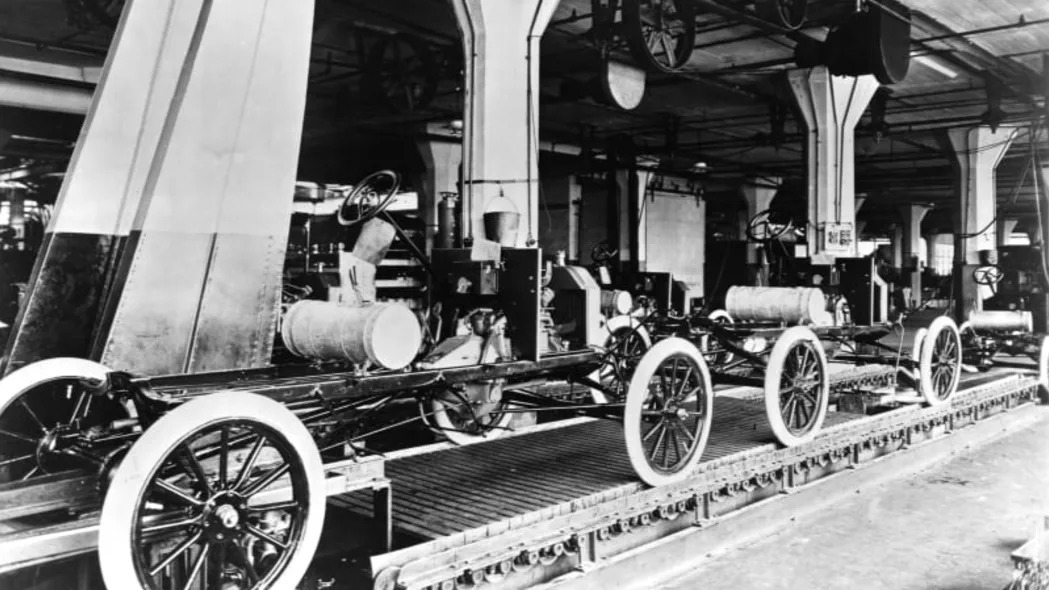

Ford's Highland Park Plant, birthplace of the manufacturing unit meeting line. (Ford)

Ford's legacy

Most mass-market automakers nonetheless largely comply with the identical fundamental setup that Henry Ford used to create the Mannequin T in 1913:

- The stamped panels are put collectively in a framing station and welded into an oblong, box-shaped automotive.

- The doorways have been put in.

- The car then goes by a paint store – both dipped in a big vat, or sprayed and dried in a big oven.

- The freshly painted doorways are then eliminated.

- Wires and an engine or motor are dropped alongside a winding meeting line.

- The seats and different inside elements are put in, after which the glass windshield and home windows are added.

- The doorways are restarted simply earlier than the ultimate inspection.

Tesla executives say the method is stuffed with inefficiencies. Shifting a car-sized “field” to a manufacturing unit (just like the one proven on the prime of this text) takes up a number of area. Portray your entire machine as a substitute of simply the important panels takes time and wastes vitality. And dealing from a hawking body means only some individuals can assemble their elements at a given time.

The unboxed technique doesn’t require a big physique of machines to be transported to a manufacturing unit. As a substitute, divided into small teams, staff work concurrently on totally different parts of a car earlier than coming collectively at one level for last meeting.

In response to Vachaparampil, the potential value financial savings are substantial. CareSoft sees at the least a 50% discount in paint-shop funding in new factories alone.

Paint has lengthy been the costliest a part of any auto plant: the excessive warmth required for automotive paint is vitality intensive, and there are strict emissions necessities. In response to auto plant specialists, the throughput of a paint store largely determines the full manufacturing of a plant.

A typical automotive physique is 6 toes (1.8 m) large and 15 toes lengthy. As a substitute of sending your entire rectangular physique by a paint store, Tesla's Unboxed course of will paint particular person panels earlier than assembling the automotive.

untested technique

The unboxed technique has its personal dangers, primarily that it’s unproven and requires modifications to a brand new meeting course of, which may delay manufacturing.

However this isn't the primary time Tesla has made vital modifications to enhance long-standing manufacturing practices.

With its Mannequin This eradicated the necessity for lots of of elements and welds.

Different American automakers are additionally working to fend off the aggressive risk posed by Chinese language vehicles. For instance, Ford Motor Firm is exploring a compact EV that might use cheap batteries.

The priority is that the underside phase of the automotive market is just not presently being served by electrical automobiles, however they are going to be served by China after the US. Firms can't lower prices,'' stated Susan Halpern, an economics professor at Case Western College who most just lately served as senior adviser for industrial technique within the White Home Workplace of Administration and Finances.

However Musk's firm has lengthy had an edge over automakers in adopting new, doubtlessly cheaper manufacturing strategies. Tesla's factories are newer than most, and a few will not be even beneath building but, so it could actually extra simply and cheaply put together its amenities to run on cutting-edge manufacturing strategies.

That doesn't imply it's straightforward. The corporate has warned buyers it’s “between two main progress waves” as demand for the Mannequin 3 and Y – each of which have languished for years – tops out. Tesla delivered 1.8 million vehicles final 12 months, however goals to ship 20 million vehicles by 2030. To do that, he would want very low-cost vehicles.